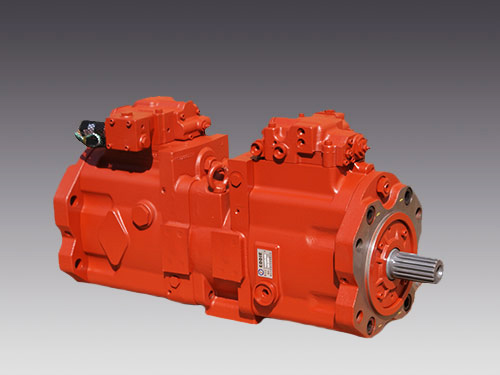

Product Overview

The F3V112DT Hydraulic Pump is designed to be a robust and efficient component within various hydraulic systems. While specific detailed technical specifications for this precise model were not extensively found, hydraulic pumps of this type are typically engineered for reliable performance and durability in demanding industrial and mobile applications.

As a critical component, it converts mechanical energy into hydraulic energy, driving various actuators and ensuring smooth and precise operation of machinery.

Key Features and Benefits

Efficiency: Designed to minimize energy loss, ensuring optimal power transmission.

Durability: Constructed with high-quality materials to withstand harsh operating conditions and provide a long service life.

Reliability: Engineered for consistent performance, reducing downtime and maintenance needs.

Versatility: Adaptable to a range of hydraulic circuits and machinery.

Precise Control: Contributes to accurate and responsive control of hydraulic functions.

Typical Product Parameters (General Hydraulic Pump Characteristics)

While specific data for F3V112DT is limited, hydraulic pumps generally feature parameters such as:

Displacement: Measured in cm³/rev, indicating the volume of fluid moved per revolution.

Max Operating Pressure: The maximum pressure the pump can withstand, typically in bar or PSI.

Max Flow Rate: The maximum volume of fluid the pump can deliver per unit of time, in L/min or GPM.

Rated Speed: The optimal operating speed of the pump, in RPM.

Mounting Type: ISO, SAE, or other standard mounting configurations.

Applicable Equipment and Application Scenarios

Hydraulic pumps like the F3V112DT are integral to various heavy-duty machinery and industrial systems that rely on hydraulic power for operation. Their robust design makes them suitable for demanding environments.

Common Equipment

Construction Equipment: Excavators, loaders, bulldozers, and cranes. These machines use hydraulics for boom, arm, bucket, and outrigger movements, requiring high power and precise control.

Agricultural Machinery: Tractors, harvesters, and specialized farming implements. Hydraulics are essential for lifting, steering, and operating various attachments.

Industrial Machinery: Presses, injection molding machines, and metal forming equipment. These applications demand high force, speed, and accuracy.

Material Handling: Forklifts, lift platforms, and conveyor systems. Hydraulics enable lifting, tilting, and moving heavy loads efficiently.

Marine and Offshore: Winches, steering gears, and propulsion systems on ships and offshore platforms, where robust and reliable power is critical.

Application Case Analysis

Case 1: Excavator Operation

In an excavator, the hydraulic pump is the heart of the system. It supplies pressurized fluid to cylinders and motors, enabling the precise and powerful movements of the boom, arm, and bucket for digging and lifting. The F3V112DT, if suitable for such applications, would ensure efficient digging cycles and smooth operation, even under heavy loads, contributing to higher productivity on construction sites.

Case 2: Industrial Press Systems

For industrial presses, consistent high pressure and flow are crucial for forming metals or molding plastics accurately. A reliable hydraulic pump minimizes pressure fluctuations, ensuring uniform product quality and reducing cycle times. The F3V112DT would provide the necessary power and stability for continuous, high-precision manufacturing operations.

Related Products and Applications

While specific alternatives to F3V112DT are not identified without its detailed specifications, hydraulic pump families generally include various types and sizes to suit diverse needs. Similar products often fall into categories based on their design and application.

Axial Piston Pumps: Known for high efficiency and pressure capabilities. They are commonly found in mobile machinery (excavators, loaders) and industrial applications (presses, test stands) requiring variable displacement.

Radial Piston Pumps: Offer high volumetric efficiency and are suitable for high-pressure, low-flow applications such as clamping systems, jacking, and certain types of machine tools.

Gear Pumps: Economical and robust, ideal for medium-pressure applications where simplicity and reliability are key. Used in agricultural machinery, power steering systems, and auxiliary circuits.

Vane Pumps: Provide good volumetric efficiency and quieter operation, often used in industrial applications like power units, material handling, and light machinery where smooth flow is desired.

Installation and Maintenance

Proper installation and regular maintenance are crucial for the longevity and efficient operation of any hydraulic pump. Neglecting these aspects can lead to premature wear, reduced performance, and costly breakdowns.

Common Issues and Solutions

Issue: Cavitation (Pump Noise, Vibrations, Reduced Performance)

Solution: Check fluid levels, ensure suction lines are free of blockages or restrictions, verify proper fluid viscosity, and inspect suction filters for clogging. Air ingress can also cause cavitation; check all suction line connections for leaks.

Issue: Overheating (High Fluid Temperature, Component Damage)

Solution: Check the cooler's efficiency, ensure proper fluid level and type, inspect for internal leakage (which generates heat), and verify the system's relief valve settings. Ensure the reservoir is adequately sized for heat dissipation.

Issue: Leakage (External Fluid Loss)

Solution: Inspect seals, O-rings, and gaskets for wear or damage and replace as necessary. Ensure all connections and fittings are properly tightened. Check for cracks in the pump housing caused by stress or impact.

Issue: Loss of Pressure/Flow (Reduced Actuator Speed or Force)

Solution: This could indicate internal wear in the pump, a faulty relief valve, or a blockage in the system. Check the pressure gauge for accurate readings, inspect the relief valve for proper function, and consider a pump overhaul or replacement if internal wear is suspected.

Issue: Contamination (Accelerated Wear, Component Failure)

Solution: Maintain strict fluid cleanliness by regularly changing filters and hydraulic fluid according to manufacturer recommendations. Implement fluid analysis to monitor contamination levels and identify potential issues early.

General Maintenance Tips

Regularly inspect the pump for signs of wear, damage, or leaks.

Maintain the correct hydraulic fluid level and ensure it's the specified type.

Change hydraulic filters at recommended intervals.

Monitor system pressure and temperature for abnormal readings.

Conduct periodic fluid analysis to assess fluid condition and detect contaminants.

Ensure proper alignment during installation to prevent excessive stress on bearings and seals.

English

English português

português Français

Français