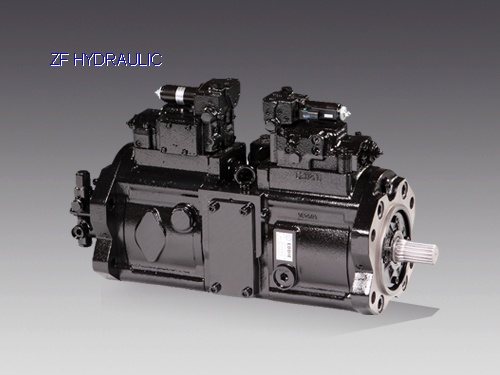

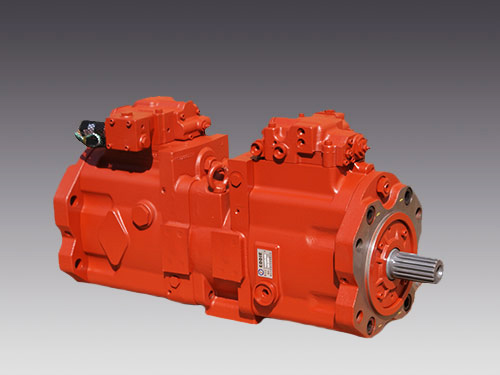

High-Performance Piston Pump: F3V112DTP-9TEL Series

Product Overview

The F3V112DTP-9TEL series represents a new generation of high-performance variable displacement axial piston pumps, engineered for demanding hydraulic applications. While specific detailed specifications for the F3V112DTP-9TEL are proprietary and vary by manufacturer, this series is designed to deliver exceptional power density, efficiency, and reliability, making it an ideal choice for sophisticated hydraulic systems requiring precise control and high pressure capabilities.

Key Product Parameters (Typical for High-Performance Axial Piston Pumps)

Please note: The following parameters are typical for high-performance variable displacement axial piston pumps of this caliber. Exact specifications for the F3V112DTP-9TEL should be confirmed with the manufacturer's official documentation.

Nominal Displacement: Ranging from 60 cm³/rev to 160 cm³/rev (e.g., 112 cm³/rev for F3V112)

Rated Pressure: Up to 350-450 bar (5000-6500 PSI) continuous

Peak Pressure: Up to 400-500 bar (5800-7250 PSI) intermittent

Speed Range: 500 – 3000 RPM (depending on displacement and operating conditions)

Flow Rate: Variable, depending on displacement and RPM (e.g., up to 200 LPM)

Control Type: Pressure compensator, load sensing, power limiting, or electro-hydraulic control options

Mounting: ISO standard 2-hole or 4-hole flange

Rotation: Clockwise, counter-clockwise, or bi-directional

Product Advantages and Selling Points

High Efficiency: Excellent volumetric and overall efficiency, reducing energy consumption and operating costs.

Exceptional Power Density: Compact design with high power output, allowing for smaller, more efficient system layouts.

Robust High-Pressure Capability: Engineered to withstand continuous operation at very high pressures, ensuring durability and reliability in demanding environments.

Precise Control: Variable displacement capability provides accurate flow control, crucial for precise machinery operation.

Long Service Life: Designed with high-quality materials and precision manufacturing for extended operational lifespan and reduced maintenance needs.

Low Noise Operation: Optimized internal geometries contribute to quieter operation, improving working conditions.

Versatile Application: Adaptable to a wide range of mobile and industrial hydraulic systems.

Suitable Equipment and Applications

The F3V112DTP-9TEL series piston pump is engineered for heavy-duty applications where high pressure, precision, and efficiency are paramount.

Construction Equipment: Excavators, loaders, bulldozers, concrete pumps, cranes, and road construction machinery.

Agricultural Machinery: Tractors, harvesters, forestry equipment requiring powerful and precise hydraulic functions.

Mining Machinery: Large-scale drilling rigs, excavators, and hauling equipment operating in harsh conditions.

Marine and Offshore Equipment: Winches, steering gear, deck machinery, and propulsion systems in marine vessels and offshore platforms.

Industrial Machinery: Metal forming presses, plastic injection molding machines, machine tools, and industrial automation systems where high force and accuracy are needed.

Oil & Gas Equipment: Drilling equipment, well intervention machinery, and fluid transfer systems.

Application Scenarios & Case Analysis

The F3V112DTP-9TEL's robust design and variable displacement capabilities make it ideal for dynamic and demanding scenarios.

Case 1: Heavy-Duty Excavator Hydraulic System

In large excavators, the F3V112DTP-9TEL pump can serve as the primary hydraulic power source, driving boom, arm, and bucket cylinders. Its variable displacement allows the excavator operator to precisely control the speed and force of movements, optimizing digging efficiency and fuel consumption. For instance, during a deep excavation, the pump can provide maximum flow for rapid arm extension, then precisely reduce flow for fine control during grading, all while maintaining high pressure to overcome heavy loads. The inherent efficiency of the pump reduces heat generation, prolonging the life of the hydraulic fluid and other components.

Case 2: Industrial Press Machine for Metal Forming

For metal stamping or forging presses, consistent and high pressure is critical. The F3V112DTP-9TEL ensures rapid approach and retraction speeds with high flow, transitioning seamlessly to precise, high-pressure pressing with controlled, low flow. This precise control over pressure and flow ensures optimal force application, preventing material deformation issues and increasing production accuracy. The pump's reliability minimizes downtime, which is crucial in high-volume industrial settings.

Related and Similar Products

While the F3V112DTP-9TEL falls under the category of variable displacement axial piston pumps, other types of hydraulic pumps serve various applications:

Axial Piston Pumps (Fixed Displacement): Offer consistent flow per revolution, suitable for applications needing constant flow without the need for variable control. Often found in simpler hydraulic circuits or as charge pumps.

Radial Piston Pumps: Known for high power density, good low-speed performance, and quiet operation. Often used in machine tools, test stands, and some heavy industrial applications where very high pressures and precise control at lower speeds are critical.

Gear Pumps: Simplest and most economical. Best suited for low to medium pressure applications (up to 250 bar) and where noise is less of a concern. Commonly found in agricultural machinery, utility vehicles, and auxiliary circuits.

Vane Pumps: Offer good efficiency and quieter operation than gear pumps, suitable for medium pressure applications (up to 180 bar). They can be fixed or variable displacement and are used in industrial power units, presses, and some mobile equipment.

Installation and Maintenance: Common Issues & Solutions

Proper installation and routine maintenance are crucial for the longevity and optimal performance of any hydraulic piston pump, including the F3V112DTP-9TEL series.

Common Issues:

Noisy Operation (Cavitation/Aeration): Often sounds like banging, knocking, or squealing. Caused by air leaks in the suction line, insufficient fluid levels, or restricted inlet.

Overheating: Can be due to excessive friction, improper fluid viscosity, contaminated fluid, or inadequate cooling.

Reduced Flow Rate/Pressure: Indicative of internal leaks (worn seals/components), fluid contamination, or blockages in the system.

Fluid Leakage: Visible leaks around seals, fittings, or pump housing, suggesting worn seals, loose connections, or internal over-pressurization.

Inconsistent Performance/Sluggish Movement: May point to worn internal components, contaminated fluid, or air in the system.

Contamination: Dirt, water, or other particles in the hydraulic fluid can severely damage internal pump components and lead to premature failure.

Solutions:

Regular Fluid Checks: Maintain proper fluid levels, ensure correct fluid type and viscosity, and regularly check for contamination. Implement scheduled oil analysis.

Inspect for Leaks: Periodically check all hydraulic lines, fittings, and seals for any signs of leakage. Replace worn seals (e.g., piston rod seals, o-rings) and tighten connections.

Maintain System Cleanliness: Ensure hydraulic filters are inspected and replaced regularly to prevent contamination.

Verify Suction Line Integrity: Check for air leaks, blockages, or restrictions in the suction line to prevent cavitation and ensure adequate fluid supply.

Monitor Temperature: Ensure the cooling system is functioning correctly and the pump operates within recommended temperature ranges.

Check for Misalignment: Proper alignment during installation is critical to prevent uneven wear on bearings and other components.

Scheduled Component Inspection: Regularly inspect internal components (pistons, cylinder block, swash plate, valves) for wear and replace as needed during routine maintenance or overhauls.

For precise technical specifications and dedicated support for your F3V112DTP-9TEL piston pump, please consult the manufacturer's official documentation or contact our support team.

Explore more hydraulic products on Hydraulic Elite

English

English português

português Français

Français