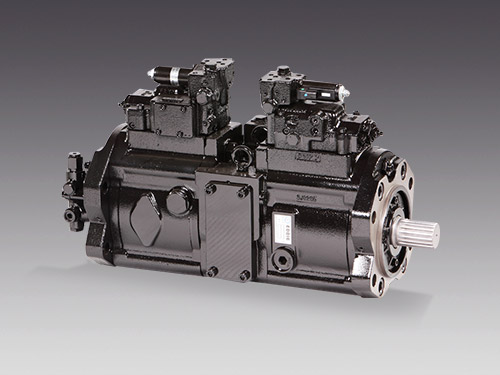

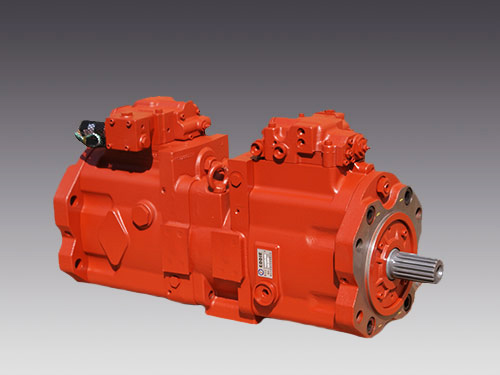

Hydraulic Main Pump K5V140DTP-YT6K for SK330-8 and SK350-8 Excavators

Your ultimate solution for excavator hydraulic systems.

Product Overview

The "K5V140DTP-YT6K Hydraulic Main Pump" is a premium, high-performance replacement part specifically engineered for "SK330-8" and "SK350-8" excavators. This main pump is the heart of your machine's hydraulic system, providing the power and precision needed for demanding construction and excavation tasks. Our pump is meticulously manufactured to meet or exceed OEM specifications, ensuring a perfect fit and reliable operation.

Investing in this high-quality hydraulic pump means restoring your excavator's performance to its peak condition. You'll experience smoother operation, improved lifting capacity, and faster cycle times, all of which contribute to enhanced productivity and efficiency on the job site.

Key Features and Product Advantages

✓ "Exceptional Durability:" Constructed from high-grade materials to withstand extreme pressure and wear, ensuring a long service life.

✓ "Superior Performance:" Delivers consistent and powerful hydraulic pressure for smooth and responsive control.

✓ "Perfect Compatibility:" Specifically designed for a direct fit and seamless integration with "SK330-8" and "SK350-8" models, eliminating the need for modifications.

✓ "Cost-Effective:" A reliable alternative to expensive OEM parts, offering premium quality without the premium price tag.

Product Specifications

| Parameter | Value |

|---|

| Model Number | K5V140DTP-YT6K |

| Applicable Excavators | SK330-8, SK350-8 |

| Type | Hydraulic Main Pump |

| Manufacturer | OEM Compatible |

Application Scenarios and Case Studies

The "SK330-8" and "SK350-8" excavators, powered by our reliable K5V140DTP-YT6K pump, are widely used in a variety of challenging environments. Their robust performance makes them ideal for tasks requiring immense power and precision.

"Construction Projects:" Perfect for digging foundations, trenching, and large-scale earthmoving operations on residential and commercial construction sites.

"Mining and Quarrying:" Used for rock breaking, material handling, and loading heavy materials into haul trucks in mining and quarry environments.

"Demolition:" The powerful hydraulic system enables these excavators to handle heavy attachments like hydraulic breakers and shears, making them suitable for dismantling old structures.

"Case Study: Urban Development Project"

A construction company was undertaking a major urban redevelopment project. Their SK350-8 excavator's original hydraulic pump began to show signs of wear, leading to slow and inconsistent boom movements. After replacing the old pump with our K5V140DTP-YT6K model, the excavator's performance was immediately restored. The team reported a 20% increase in digging efficiency and a significant reduction in downtime, allowing them to meet their project deadlines ahead of schedule.

Related Products

In addition to the K5V140DTP-YT6K, we offer a wide range of hydraulic components to keep your machinery running smoothly. Consider these similar products:

Kawasaki K5V160 Main Pump

"Applicable Equipment:" Larger excavators like the SK480 and other heavy-duty machinery. Ideal for applications requiring even greater flow and pressure.

Sauer-Danfoss SPV20 Hydraulic Pump

"Applicable Equipment:" Used in a variety of compact excavators and smaller construction equipment, providing excellent control and efficiency.

Rexroth A10VO Variable Pump

"Applicable Equipment:" Common in a wide range of mobile machinery, including loaders and dozers, known for its energy-saving features and precise control.

Common Installation & Maintenance Issues

Issue 1: Cavitation and Noise

"Problem:" A whining or rattling sound coming from the pump, often accompanied by erratic performance. This is typically caused by air entering the hydraulic system.

"Solution:" Check the suction line for leaks and ensure all connections are tight. Verify that the hydraulic fluid level is correct and that the filter is not clogged. Proper bleeding of the system after installation is crucial to remove any trapped air.

Issue 2: Overheating

"Problem:" The pump and hydraulic fluid become excessively hot, which can lead to premature wear and seal failure.

"Solution:" Check the fluid level and ensure the correct type of hydraulic oil is being used. Clean the hydraulic cooler to ensure proper heat dissipation. An overloaded system or a malfunctioning relief valve can also cause overheating, so it's important to inspect these components.

Issue 3: Loss of Pressure or Weak Performance

"Problem:" The excavator's movements are slow, or it struggles to lift heavy loads. This indicates a loss of hydraulic pressure.

"Solution:" This can be caused by various factors, including worn-out internal components, a faulty pressure regulator, or a leak in the system. A professional diagnosis is recommended to pinpoint the exact cause. Regular maintenance, including changing filters and fluid, can prevent these issues.

English

English português

português Français

Français