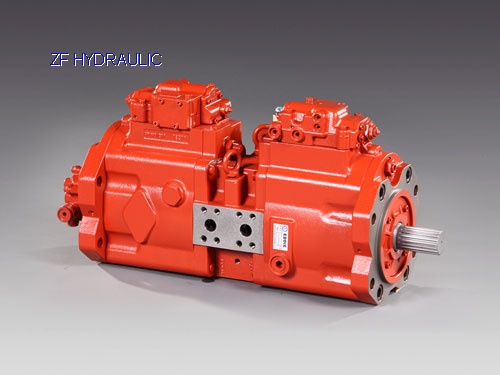

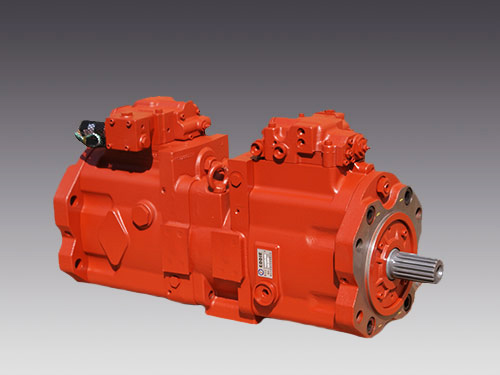

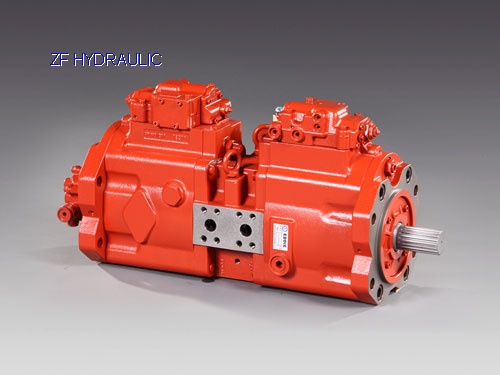

F3V180DT

Axial Piston Pump

Welcome to the next generation of hydraulic power. The "F3V180DT Swashplate-Type Axial Piston Pump" is a pinnacle of hydraulic engineering, designed for applications demanding high power, exceptional efficiency, and robust reliability. This pump stands out in the industry for its precise control and adaptable design, making it a cornerstone for a wide range of heavy-duty machinery.

Product Specifications & Technical Parameters

Model: F3V180DT

Displacement: 180 cm³/rev

Rated Pressure: 350 bar

Max Pressure: 400 bar

Speed Range: 500-2000 rpm

Mounting Flange: ISO 3019/2 (SAE B 2-hole)

Control Type: Pressure Compensator (DT)

Fluid: Mineral oil

Key Features & Advantages

High Efficiency: The swashplate design ensures minimal power loss and high volumetric efficiency, translating to reduced energy consumption and operational costs.

Robust Durability: Constructed with high-grade materials and precision engineering, the F3V180DT is built to withstand extreme operating conditions and provide a long service life.

Precise Control: The integrated "DT (Pressure Compensator)" control allows for fine-tuned pressure regulation, ensuring a stable and consistent output that protects both the pump and the system.

Compact Design: Despite its powerful performance, its compact size allows for easy integration into existing or new hydraulic systems where space is a premium.

Applications & Use Cases

The F3V180DT is a versatile powerhouse, ideal for a wide array of heavy machinery. Its robust nature and precise control make it a top choice for demanding environments.

Construction Equipment: It powers the hydraulic systems in excavators, bulldozers, and cranes, where its high pressure and reliable performance are crucial for lifting, digging, and grading.

Mining Machinery: Used in drilling rigs, loaders, and haul trucks, it withstands the harsh, dusty conditions of mining operations, ensuring consistent power for rock crushing and material handling.

Agricultural Equipment: In large tractors, harvesters, and irrigation systems, the F3V180DT provides the muscle for demanding tasks like plowing and operating heavy implements.

Application Case Study: Large-Scale Excavator

A leading manufacturer of construction machinery integrated the F3V180DT into their new line of heavy-duty excavators. The pump's pressure-compensated control allowed for a smoother, more precise swing and boom movement, reducing operator fatigue and increasing digging accuracy. The pump's high volumetric efficiency led to a 10% reduction in fuel consumption compared to previous models, significantly lowering operational costs for end-users. This successful implementation cemented the F3V180DT's reputation for performance and efficiency in real-world applications.

Related Products

For different performance requirements, we offer a range of similar high-quality axial piston pumps:

F1V130DT: A smaller displacement model (130 cm³/rev) suitable for medium-duty applications such as compact loaders, skid steers, and mobile cranes.

F3V250DT: A larger displacement model (250 cm³/rev) for exceptionally heavy-duty tasks, including large mining excavators, rock crushers, and marine winches.

Installation & Maintenance Guide

Common Issues & Solutions

Issue: "Pump Noise."

Cause: Often caused by cavitation, air ingress, or a misaligned shaft.

Solution: Check the suction line for leaks, ensure the fluid level is correct, and bleed any trapped air. Verify the pump is properly aligned with the prime mover to prevent shaft stress.

Issue: "Low Pressure/Flow Output."

Cause: Worn internal components, a faulty pressure compensator, or contaminated fluid.

Solution: Inspect the pressure compensator setting. If the issue persists, the pump may need to be disassembled and inspected for internal wear. Ensure the hydraulic fluid is clean and within specifications.

Issue: "Overheating."

Cause: High fluid viscosity, low fluid level, or a faulty heat exchanger.

Solution: Use the correct grade of hydraulic oil. Ensure the reservoir has adequate fluid and that the heat exchanger is functioning correctly and is free of blockages.

English

English português

português Français

Français