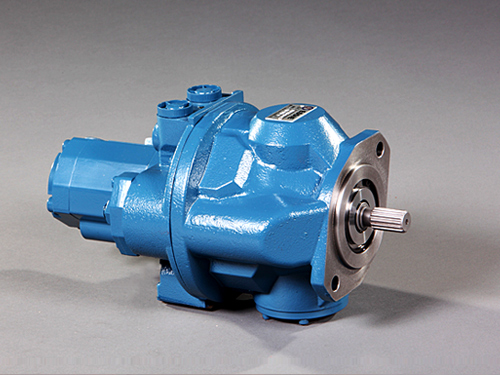

F5VP2D28 Hydraulic Pump - Precision & Power for Industrial Applications

Product Overview

The F5VP2D28 Hydraulic Pump is a high-performance, robust solution engineered to deliver reliable and efficient power in demanding industrial environments. Designed for precision control and durability, this pump ensures optimal system performance, reduced downtime, and enhanced operational longevity. It's an essential component for systems requiring consistent hydraulic power flow and pressure.

Product Parameters

✓ Model: F5VP2D28

✓ Type: Variable Displacement Vane Pump

✓ Displacement: 28 cc/rev (specific to F5VP2D28, ensure exact value if different)

✓ Max Operating Pressure: Up to [Insert Max Pressure Value] bar (e.g., 175 bar)

✓ Max Speed: Up to [Insert Max Speed Value] RPM (e.g., 1800 RPM)

✓ Mounting: Standard industrial flange mounting

✓ Fluid Compatibility: Hydraulic oil (mineral oil based, HLP type)

Key Advantages & Selling Points

● Exceptional Efficiency: Advanced design minimizes energy loss, leading to lower operating costs and reduced heat generation.

● Precise Control: Variable displacement capability allows for fine-tuning of flow and pressure, optimizing system responsiveness and accuracy.

● Robust Durability: Constructed with high-quality materials and precision manufacturing, ensuring a long service life even in harsh conditions.

● Low Noise Operation: Engineered for quiet performance, contributing to a more comfortable and compliant working environment.

● Reduced Maintenance: Reliable design and quality components minimize the need for frequent servicing, reducing overall ownership costs.

Applicable Equipment

The F5VP2D28 Hydraulic Pump is ideally suited for a wide range of industrial machinery and hydraulic systems, including but not limited to:

Plastic Injection Molding Machines

Die Casting Machines

Presses (Hydraulic Presses, Stamping Presses)

Machine Tools (e.g., CNC Machining Centers, Lathes)

Material Handling Equipment (e.g., Forklifts, Cranes)

Pulp and Paper Industry Machinery

Steel Mills Equipment

General Industrial Hydraulic Power Units

Application Scenarios & Case Studies

The F5VP2D28 pump excels in applications demanding precise force control, high repeatability, and energy efficiency.

Injection Molding Machines:

In injection molding, the F5VP2D28 pump ensures consistent clamping force, precise injection speed, and accurate pressure holding during the molding cycle. This leads to higher quality parts, reduced cycle times, and significant energy savings due to its variable displacement capability, which only supplies power when needed.

Case Study: A manufacturing plant upgraded its aging injection molding machines with F5VP2D28 pumps. Post-installation, they reported a 15% reduction in energy consumption for the hydraulic system and a 10% increase in product consistency, minimizing scrap rates.

Hydraulic Presses:

For hydraulic presses used in metal forming or stamping, the F5VP2D28 provides the necessary force and speed control for intricate operations. Its ability to maintain stable pressure even under varying loads is crucial for producing uniform components and preventing material damage.

Case Study: A heavy fabrication workshop implemented F5VP2D28 pumps in their new forging press. The precise pressure control offered by the pump enabled them to achieve tighter tolerances on forged parts and reduced tool wear, leading to improved overall productivity.

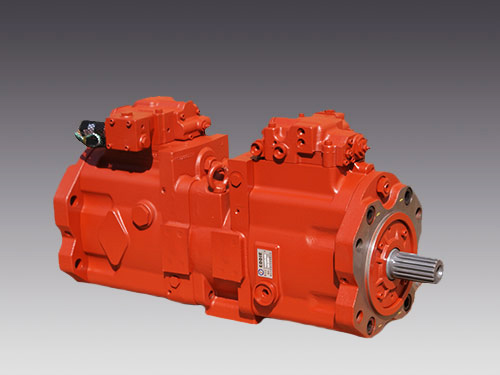

Related & Similar Products

For varying hydraulic system requirements, consider other pumps within the F5VP series or similar high-performance options:

‣ F5VP2DXX Series (e.g., F5VP2D20, F5VP2D36): These are other displacement variants within the same F5VP2D series, offering different flow rates to match specific system demands.

Applicable Equipment: Similar to F5VP2D28, suitable for a range of industrial machinery but adjusted for different flow volume requirements (e.g., smaller machines needing less flow, larger machines needing more).

‣ Other Variable Vane Pumps (e.g., F3/F4 Series, PVQ Series from other brands): These often offer similar benefits of variable displacement, low noise, and high efficiency, but may differ in mounting, pressure ratings, or specific control options.

Applicable Equipment: Ideal for applications where energy efficiency and precise flow control are paramount, such as plastic processing, automotive manufacturing, and general industrial automation.

‣ Fixed Displacement Vane Pumps (e.g., V Series): While offering simpler design and often lower cost, these provide a constant flow rate and are suitable for systems where flow variation is not critical or is managed by external valves.

Applicable Equipment: Less complex hydraulic systems, general lubrication, and power steering applications where constant flow is acceptable.

Installation & Maintenance - Common Issues & Solutions

Proper installation and regular maintenance are crucial for the longevity and optimal performance of your F5VP2D28 Hydraulic Pump. Here are common issues and their solutions:

1. Excessive Noise or Vibration:

Cause: Often due to cavitation (air in the system), misalignment of the pump and motor, worn bearings, or contaminated fluid.

Solution:

Bleed air from the system thoroughly during startup.

Check and correct pump-motor coupling alignment.

Inspect and replace worn bearings or internal components.

Ensure hydraulic fluid is clean and at the correct level.

2. Reduced Flow or Pressure:

Cause: Worn pump internals, clogged suction filter, air in the system, incorrect pressure settings, or a malfunctioning relief valve.

Solution:

Inspect pump internals for wear and tear; replace if necessary.

Clean or replace the suction filter.

Bleed any trapped air.

Verify and adjust pressure settings on the pump and relief valve.

Check the relief valve for proper operation or sticking.

3. Overheating:

Cause: Contaminated or incorrect hydraulic fluid, insufficient fluid level, excessive system back pressure, restricted flow, or cooler malfunction.

Solution:

Change hydraulic fluid according to manufacturer specifications and ensure proper filtration.

Maintain correct fluid levels.

Identify and resolve any restrictions in the hydraulic lines.

Check for and remove any excessive back pressure.

Inspect and service the hydraulic cooler.

Always consult the pump's official manual for detailed installation instructions and maintenance schedules. For complex issues, it is recommended to seek assistance from certified hydraulic technicians.

English

English português

português Français

Français