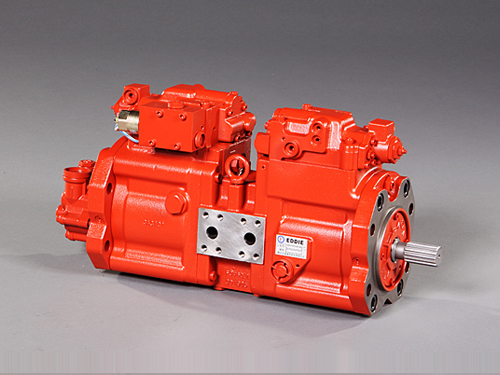

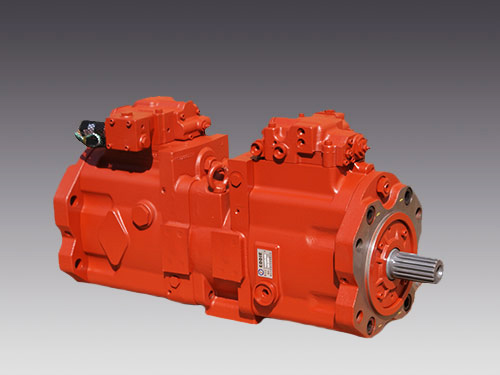

F3V63dt, F3V112dt, F3V140dtp Hydraulic Pump Axial Piston Swash Plate for Excavators

Unleash peak performance and reliability in your heavy machinery with our premium "F3V63dt, F3V112dt, and F3V140dtp Hydraulic Pump Axial Piston Swash Plate". Engineered for demanding excavation tasks, these hydraulic pumps are the heart of your equipment, ensuring smooth, powerful, and efficient operation.

Product Specifications

"Model Numbers:" F3V63dt, F3V112dt, F3V140dtp

"Type:" Axial Piston Swash Plate Hydraulic Pump

"Displacement (approx.):"

F3V63dt: 63 cc/rev

F3V112dt: 112 cc/rev

F3V140dtp: 140 cc/rev

"Rated Pressure:" Up to 350 bar (5075 psi)

"Peak Pressure:" Up to 400 bar (5800 psi)

"Control Type:" Pressure compensator, flow compensator, power limiter (depending on model)

"Rotation:" Clockwise or Counter-clockwise (reversible options available)

"Material:" High-grade alloys for durability and wear resistance

Key Advantages & Selling Points

"Exceptional Durability:" Built with robust materials and precision engineering to withstand harsh operating conditions and extend service life.

"Optimized Efficiency:" Advanced swash plate design ensures minimal energy loss, leading to reduced fuel consumption and increased productivity.

"Precise Control:" Delivers accurate and responsive hydraulic power, allowing for smooth and precise operation of excavator attachments.

"Reduced Noise & Vibration:" Engineered for quieter operation and less vibration, improving operator comfort and reducing machine fatigue.

"Easy Integration:" Designed for seamless replacement and compatibility with a wide range of excavator models.

"Reliable Performance:" Consistent power output and stable operation even under heavy loads and continuous use.

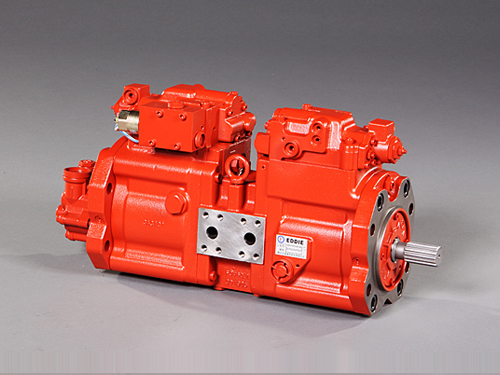

Ideal Equipment Applications

These hydraulic pumps are specifically designed for a variety of "excavator models", including but not limited to:

"Compact Excavators:" Ideal for tasks in confined spaces.

"Medium Excavators:" Perfect for general construction, utility work, and landscaping.

"Large Excavators:" Suited for heavy-duty digging, mining, and demolition projects.

"Wheel Excavators:" Providing mobility and versatility on various job sites.

"Crawler Excavators:" Offering maximum stability and traction for demanding terrains.

Application Scenarios & Case Studies

Our F3V series hydraulic pumps excel in diverse operational environments, delivering consistent power and control.

"Construction Sites:" Excavators equipped with our pumps efficiently handle trenching, foundation digging, and material loading.

"Case Study:" A construction company reported a 15% improvement in digging cycle times after upgrading their fleet's hydraulic pumps to our F3V112dt model, significantly boosting project completion rates.

"Mining Operations:" In harsh mining conditions, these pumps provide the necessary power for continuous excavation and material handling, ensuring minimal downtime.

"Case Study:" A large open-pit mine experienced extended hydraulic system lifespan and reduced maintenance costs by adopting F3V140dtp pumps in their heavy excavators, even in extreme temperatures and dusty environments.

"Road Building & Infrastructure:" Essential for tasks like grading, paving preparation, and culvert installation, where precise hydraulic control is paramount.

"Case Study:" During a major highway expansion project, excavators featuring our F3V63dt pumps demonstrated superior fine-grading capabilities, contributing to a smoother and more durable road surface.

"Demolition Projects:" The pumps' robust design ensures they can withstand the shock loads associated with breaking and crushing concrete and other heavy materials.

"Case Study:" A demolition contractor highlighted the consistent power delivery of our pumps as critical for the efficient operation of hydraulic hammers and pulverizers during a multi-story building demolition.

Related & Similar Products

Beyond the F3V series, we offer a comprehensive range of hydraulic pumps suitable for various heavy equipment:

Common Installation & Maintenance Issues and Solutions

Proper installation and routine maintenance are crucial for maximizing the lifespan and performance of your hydraulic pump. Here are some common issues and their solutions:

"Issue: Reduced Power Output or Slow Operation"

"Possible Causes:" Low hydraulic fluid level, contaminated fluid, worn pump components, clogged filters, or air in the system.

"Solutions:" Check and top up fluid to the correct level, replace contaminated fluid and filters, inspect and replace worn seals or pistons, and bleed the hydraulic system to remove air.

"Issue: Excessive Noise or Vibration"

"Possible Causes:" Cavitation (air in fluid), misaligned pump and engine, loose mounting bolts, or worn bearings.

"Solutions:" Ensure proper fluid level and quality, check and correct alignment, tighten all mounting bolts, and replace damaged bearings.

"Issue: Overheating Hydraulic System"

"Possible Causes:" Insufficient fluid cooling, clogged cooler, system overload, or internal pump leakage.

"Solutions:" Clean or replace the hydraulic cooler, ensure the system is not operating beyond its design capacity, and inspect the pump for internal wear causing leakage.

"Issue: External Leaks"

"Possible Causes:" Damaged seals, loose fittings, or cracked housing.

"Solutions:" Replace worn or damaged seals (e.g., shaft seals, O-rings), tighten all hydraulic fittings, and inspect the pump housing for cracks.

"General Maintenance Tip:" Always use the manufacturer-recommended hydraulic fluid, adhere to scheduled fluid and filter changes, and regularly inspect hoses and fittings for wear and tear.

English

English português

português Français

Français