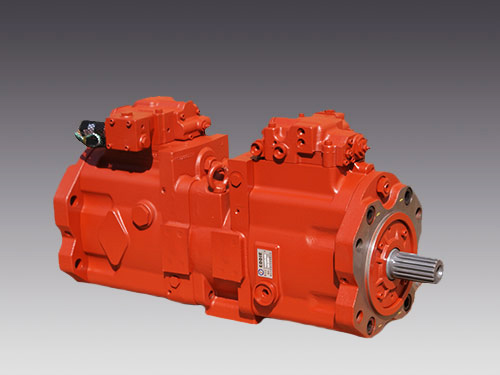

Product Overview

The FPSV2D27 Hydraulic Pump is a robust and efficient solution engineered for demanding industrial hydraulic systems. Designed for reliability and sustained performance, this pump is ideal for applications requiring precise control and high power output. Its advanced design ensures minimal energy loss and extended operational life, making it a valuable asset for a wide range of machinery.

Applicable Equipment and Application Scenarios

The FPSV2D27 Hydraulic Pump is highly suitable for a broad spectrum of industrial and mobile equipment, including:

Construction Machinery: Excavators, loaders, bulldozers, concrete pumps, cranes.

Agricultural Equipment: Tractors, harvesters, sprayers, irrigation systems.

Industrial Presses: Hydraulic presses for stamping, forging, bending.

Plastics Processing Machinery: Injection molding machines, blow molding machines.

Metalworking Machinery: CNC machines, milling machines, grinding machines requiring hydraulic clamping or tool changing.

Material Handling Equipment: Forklifts, lift tables, aerial work platforms.

Marine Applications: Winches, steering gear, deck machinery.

Application Scenario and Case Analysis:

Consider an Injection Molding Machine. In this context, the FPSV2D27 hydraulic pump is crucial for providing precise and responsive hydraulic power to control the mold clamping, injection, and ejection processes. The pump's variable displacement capability allows it to deliver only the required flow and pressure, significantly reducing energy consumption compared to fixed displacement pumps, especially during holding and cooling phases. This leads to substantial cost savings over time and reduced heat generation. A real-world case might involve a manufacturer upgrading their existing injection molding machines with FPSV2D27 pumps, resulting in a 15-20% reduction in energy costs and improved cycle times due to more efficient hydraulic response. The low noise characteristic also contributes to a quieter factory environment.

Another example is in Heavy-Duty Excavators. Here, the FPSV2D27 pump can be utilized for powering the swing mechanism, boom, and bucket cylinders. Its robust construction ensures reliability in harsh outdoor conditions, and its high pressure capability enables powerful digging and lifting operations. The load-sensing control option ensures that the pump delivers flow only when demand is present, optimizing fuel efficiency. In a typical scenario, an construction company replaced a failing pump in one of their excavators with an FPSV2D27 unit, experiencing not only restored performance but also a noticeable improvement in fuel economy, which translates directly into lower operational expenses for large fleets.

English

English português

português Français

Français