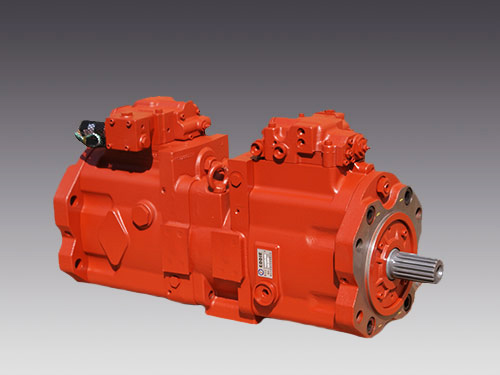

F5V80DT Hydraulic Pump - Precision and Power for Demanding Applications

The F5V80DT Hydraulic Pump is a robust and high-performance solution engineered to meet the demanding requirements of various industrial and mobile applications. Designed for efficiency and durability, this pump ensures reliable power transmission and precise control, crucial for optimizing operational productivity.

Product Parameters

Model: F5V80DT

Type: Variable Displacement Vane Pump

Displacement: 80 cm³/rev

Max. Operating Pressure: Up to 210 bar (3045 psi)

Max. Speed: Up to 1800 rpm

Mounting: SAE 2-bolt flange

Shaft: Keyed shaft

Fluid Compatibility: Mineral oils, synthetic fluids

Key Advantages and Selling Points

High Efficiency: Optimized design minimizes energy loss, leading to reduced operating costs.

Precise Control: Variable displacement capability allows for accurate flow and pressure regulation, enhancing system responsiveness.

Durability: Constructed with high-quality materials and robust engineering for extended service life in harsh environments.

Low Noise Operation: Engineered for quiet performance, contributing to a more comfortable working environment.

Versatile Application: Suitable for a wide range of hydraulic systems due to its adaptable design and performance characteristics.

Easy Integration: Standard mounting options and shaft configurations facilitate straightforward installation and replacement.

Applicable Equipment and Application Scenarios

The F5V80DT Hydraulic Pump is ideally suited for equipment requiring reliable and controlled hydraulic power. Its versatility makes it a critical component in various industries.

Related Similar Products

In addition to the F5V80DT, we offer a range of hydraulic pumps designed to meet diverse application needs.

F5V Series Variable Vane Pumps:

Models: F5V20, F5V40, F5V60, F5V100 (with varying displacements)

Applicable Equipment: Smaller construction equipment, municipal vehicles, industrial power units requiring lower flow rates, and specific agricultural machinery.

Piston Pumps (e.g., A10VSO Series):

Characteristics: Higher pressure capabilities and often more compact for their power output.

Applicable Equipment: Heavy-duty construction machinery (large excavators, concrete pumps), marine applications, and specialized industrial equipment requiring very high pressures and precise control.

Gear Pumps (e.g., G Series):

Characteristics: Fixed displacement, simpler design, and cost-effective.

Applicable Equipment: Auxiliary circuits in construction machinery, agricultural tractors (for basic functions), small lifting equipment, and various industrial applications where fixed flow is acceptable.

Common Installation and Maintenance Issues & Solutions

Issue: Excessive Noise or Vibration

Causes: Air cavitation due to clogged inlet filter or insufficient fluid level, misaligned pump/motor, worn bearings, or improper fluid viscosity.

Solutions: Check hydraulic fluid level and quality, replace clogged filters, ensure proper alignment during installation, and use the recommended hydraulic fluid.

Issue: Overheating

Causes: Contaminated fluid, low fluid level, excessive system pressure, restricted return line, or cooler malfunction.

Solutions: Regularly check and replace hydraulic fluid, maintain proper fluid levels, verify system pressure settings, inspect and clear return lines, and ensure the cooler is functioning correctly.

Issue: Reduced Flow or Pressure Output

Causes: Internal wear (vane tips, cam ring), relief valve malfunction, air in the system, or a faulty control mechanism.

Solutions: Conduct regular fluid analysis to detect wear particles, inspect and adjust relief valve settings, bleed air from the system, and check the functionality of the pump's control mechanism.

Issue: Leaks Around Seals or Connections

Causes: Worn or damaged seals, improper torque on fittings, or cracks in the housing.

Solutions: Replace worn seals and O-rings, ensure all connections are torqued to manufacturer specifications, and inspect the pump housing for any signs of damage.

General Maintenance Tips:

Regularly inspect the pump and associated components for signs of wear or damage.

Adhere to the manufacturer's recommended maintenance schedule.

Use only high-quality, clean hydraulic fluid and genuine replacement parts.

Train personnel on proper operational and maintenance procedures.

English

English português

português Français

Français